The effects of calcium propionate in the environment are multi-faceted, and are analyzed in the following aspects:

Stability: Calcium propionate is more stable in the environment, which means that its chemical properties are not easy to change under natural environmental conditions, and it can maintain its own structure and properties for a certain period of time.

Degradability: Calcium propionate is not easy to be degraded, it is difficult to be quickly converted into other substances in the natural environment through natural ways such as microbial decomposition, and may exist in the environment for a long time.

Production and use process: In the production and use process of calcium propionate, care needs to be taken to prevent environmental pollution. Although it itself has a low impact on the environment, the production process may produce some waste and wastewater, etc., which, if not handled properly, may have an adverse effect on the surrounding environment. For example, wastewater discharged during the production process may cause damage to water ecosystems if it contains untreated calcium propionate or other chemical substances; during use, if a large amount of calcium propionate enters the soil in an unreasonable manner, it may affect the soil's acidity and alkalinity and the structure of microbial communities, etc.

Stevia, also known as stevia glycoside and commonly known as stevia, is a new type of natural sweetener extracted from stevia (or stevia leaf), an herb of the Asteraceae family.123 The following will be a detailed description of its source, composition, properties, characteristics, safety and scope of use in various aspects:

Source and Composition

Plant Source: Stevia is originally from Paraguay and Brazil, and is now cultivated in China, Singapore, Nowadays, it is also grown in China, Singapore, Malaysia and other countries. Stevioside is a kind of glycoside extracted from the leaves of stevia.

Composition: The sweet component consists of stevioside and stevia A glycoside, B glycoside, C glycoside, D glycoside and E glycoside.

Physical and Chemical Properties

Appearance and Status: white to slightly yellow crystalline powder or granule, with cool sweet odor.

Solubility: soluble in water, in the air will quickly absorb moisture, solubility at room temperature more than 40%.

Stability: stable in acid and salt solutions, more stable nature at room temperature. Very stable in pH 3 - 10 range, easy to store. Good solution stability, in the general beverage food pH range, heat treatment is still very stable. In the organic acid containing sucrose solution stored for half a year with little change; in the acid and alkali medium does not decompose, can prevent fermentation, discoloration and precipitation.

Characteristics

High sweetness: the sweetness is 250 - 450 times that of sucrose, but with a slight astringent flavor, stevia A glycoside with obvious bitterness and a certain degree of astringency and menthol flavor, taste characteristics to be worse than stevia disaccharide glycoside A, moderately palatable, the aftertaste of the pure product is less, it is the closest to granulated sugar as a natural sweetener, but the concentration of a high level of off-flavors will have a strange sense. The sweetness of the purified Rebaudioside A sugar is about 450 times sweeter than sucrose, with a better taste.

Low calorie: It is not absorbed after consumption and does not produce calories, so it is a good natural sweetener for diabetes and obesity patients.

Flavor synergy: with citric acid or glycine and good taste; with sucrose, fructose and other sweeteners, taste quality is better. When it is used with citric acid, tartaric acid, amino-acids, etc., it has the effect of killing the aftertaste of steviol glycosides, so it can play the role of correcting the flavor when mixed with the above substances, and improve the quality of the sweet taste of steviol glycosides.

Dissolution characteristics: dissolution temperature and sweetness of the taste of the relationship between the general low-temperature dissolution of high sweetness; high-temperature dissolution after the taste of good but low sweetness.

Safety

The acute toxicity test of Stevia shows that the oral LD50 of stevia crystals in mice is 16g/kg. Preclinical and clinical studies have shown that the use of stevia extract is safe for the general population, including diabetics, children and pregnant women, as well as people with unknown side effects or allergies. It has been consumed by residents of its origin (Paraguay, Brazil and other places in South America) for hundreds of years, and no toxic effects have been found so far.

China's National Standard for Food Safety, Standard for the Use of Food Additives (GB2760 - 2014) clearly stipulates the scope of use and the amount of steviol glycosides.

Scope of use

Food field: it can be used in all kinds of food, such as candy, pastry, beverage, solid beverage, fried small food, seasoning, candied fruit and so on. It can also be used in the production of chewing gum, bubble gum and candies with various flavors; it is used in the manufacture of hard candy together with lactose, maltose syrup, fructose, sorbitol, maltitol and lactone sugar. In addition, it can be used in canned food (canned fruits, aquatic products and canned meat, etc.), pickled products (radish and other pickles, squash), aquatic products (canned fish, kelp, etc.), and meat food (sausage, ham, bacon, etc.), which can play the role of seasoning, antiseptic, prolonging the shelf life, and improving the flavor.

Beverage field: It can be used in soft drinks, orange juice, various fruit juices, ice cream, beer, fruit wine, white wine and other beverages. It can be used in beverages to increase the sweetness, reduce the pungency of wine, and increase the whiteness and durability of beer foam.

Other fields: It can also be used in cigarettes, milk powder and other products, and can also be used as a ripening agent for fruits and vegetables, and used for salt-free storage of foodstuffs.

Enhance Your Product Appeal with Customized 18-410 18 mm Aluminum Shell Pipette Dropper

In a world where product differentiation is essential, customization plays a pivotal role in creating a unique identity for your offerings. When it comes to packaging, the 18-410 18 mm Customized Color Aluminum Shell Pipette Dropper stands out as a versatile solution that not only meets functional requirements but also enables you to tailor its appearance to match your brand aesthetics. In this blog post, we'll explore the various customization options available for the aluminum shell, rubber color, and embossed logo, highlighting how they can elevate your product's appeal and make it truly stand out from the competition.

Customizable Aluminum Shell Color:

The cangnuopack 18-410 18 mm Pipette Dropper comes with the advantage of customizable aluminum shell colors. You have the freedom to choose from a range of eye-catching options that include rose gold, glossy gold, matte silver, and glossy silver. By selecting a color that aligns with your brand identity or product theme, you can create a harmonious visual presentation that resonates with your target audience. Whether you aim for a sleek and modern appearance or a luxurious and elegant feel, the customized aluminum shell color lets you achieve the desired effect.

Customizable Rubber Color:

In addition to the aluminum shell color, the 18-410 18 mm Pipette Dropper provides the flexibility to customize the rubber color of the dropper bulb. The range of available options includes vibrant yellow, classic black, and pristine white. The rubber color can be chosen to complement your brand colors, create a strong visual contrast, or convey a specific product attribute. It's an opportunity to infuse your brand personality into the packaging, increasing its visual appeal and making a lasting impression on your customers.

Customized Embossed Logo:

The 18-410 18 mm Pipette Dropper takes personalization to the next level by offering customized embossed logos on the aluminum shell. This feature helps you elevate your brand recognition and create a memorable product identity. By imprinting your logo directly onto the aluminum surface, you provide a premium and professional touch that communicates a sense of quality and craftsmanship. This customization option ensures that your product stands out not only on store shelves but also when it's in use, reinforcing brand awareness and fostering customer loyalty.

Benefits of Customization:

- Brand Differentiation: customization allows you to create a unique packaging design that differentiates your product from competitors, catching the eye of potential customers.

- Brand Consistency: by aligning the aluminum shell and rubber color with your brand palette, you maintain a consistent visual identity across all your products, strengthening brand recognition.

- Enhanced Perceived Value: customization adds a touch of exclusivity and sophistication to your packaging, making it appear more valuable and premium to consumers.

- Memorable User Experience: the embossed logo provides a tactile experience that elevates the perceived quality of your product, leaving a lasting impression on users.

The 18-410 18 mm Customized Color Aluminium Shell Pipette Dropper is a versatile and customizable solution that combines functionality with aesthetics. By offering a wide range of customization options, such as the color of the aluminium shell, rubber, and embossed logo, you can create a unique and attention-grabbing product that reflects your brand identity. Whether you are in the cosmetics, pharmaceutical, or other industries that require precise and controlled dispensing, this custom dropper will meet your needs while adding a touch of elegance. Invest in the 18-410 18 mm Customized Color Aluminium Shell Pipette Dropper and set yourself apart in the market with a personalized and high-quality product.

The 18-410 18 mm Customized Color Aluminium Shell Pipette Dropper can be used for various products that require precise dispensing or sampling. Some common applications include:

- Essential oils: The pipette dropper is useful for dispensing small quantities of essential oils for aromatherapy, skincare products, or DIY projects.

- Cosmetics: It can be used for precise dispensing of serums, facial oils, and other liquid cosmetic products.

- Pharmaceuticals: The dropper is suitable for dispensing medications, tinctures, or liquid supplements in pharmaceutical applications.

- Laboratory and scientific use: It can be used for accurate measurement and dispensing of reagents, chemicals, or samples in a laboratory setting.

- Food and beverage industry: The dropper can be used for dispensing flavorings, food colorings, or liquid additives in the food and beverage industry.

- E-liquids: It can be used for precision filling of e-cigarettes or vaporizers with e-liquid.

- DIY projects and crafts: The dropper is handy for various crafting projects, such as adding small amounts of dyes, inks, or pigments to art materials.

These are just a few examples, and the applicability of the dropper can extend to other industries or products requiring accurate and controlled dispensing of liquids. It's important to ensure that the specific product and its compatibility with the dropper are verified before use.

When it comes to Korean BBQ grills, most people focus on design, heat output, and cooking performance. But there’s one component that is often over looked—and it's more important than you might think: the power cord.

In this article, we’ll explain why choosing the right power cord for your Korean BBQ grill is critical, how it affects safety and performance, and what to look for when evaluating power cords for your restaurant or business.

Why the Power Cord Matters

The power cord is the life line of any electric Korean BBQ grill. It delivers the electricity needed to heat the grill quickly and maintain a consistent temperature. A low-quality or unsuitable power cord can lead to:

-

Overheating

-

Voltage drops

-

Fire hazards

-

Shortened equipment lifespan

In other words, the performance and safety of your grill largely depend on the power cord.

Key Impacts of Power Cord Quality

1.Safety

A poor-quality or under-rated cord can overheat and even melt, posing a serious fire risk. Using a certified, heat-resistant cable with the correct amperage and voltage rating ensures safe operation—even during long hours of use.

2.Stable Performance

An undersized or inferior cord can lead to voltage drops, causing the grill to heat unevenly or fail to reach the desired temperature. This can directly affect cooking quality and customer satisfaction.

3.Durability

High-quality cords are built to withstand the constant plugging, unplugging, bending, and exposure to heat and grease that come with commercial kitchen use. Investing in a durable cord means fewer replacements and less downtime.

4.Compliance

Most countries have strict electrical safety standards. Using certified power cords (e.g. UL, CE, or other local standards) helps ensure your grill setup complies with local regulations—especially important for restaurants undergoing inspections.

What to Look for in a Good Power Cord

When choosing or replacing a power cord for a Korean BBQ grill, consider the following:

-

Voltage and amperage rating: Match the grill’s requirements (e.g., 110V/220V, 10A/15A).

-

Heat resistance: Ensure the insulation can handle high temperatures.

-

Cable thickness: Thicker cables carry current more safely and efficiently.

-

Length: Use the correct length—too short limits flexibility; too long can cause voltage drops.

-

Certifications: Look for marks like UL, CE, or national safety approvals.

Our Commitment to Quality Power Cords

We understand that the power cord is not just a simple accessory—it’s a critical safety and performance component of every Korean BBQ grill we manufacture.

That’s why westrictly use internationally certified power cords, sourced from trusted suppliers and tested to meet global safety standards. All our cables are:

-

UL / CE / CCC certified(depending on customer region)

-

Made withheat-resistant insulation

-

Rated forhigh current and long-term use

-

Built to withstand demanding commercial kitchen environments

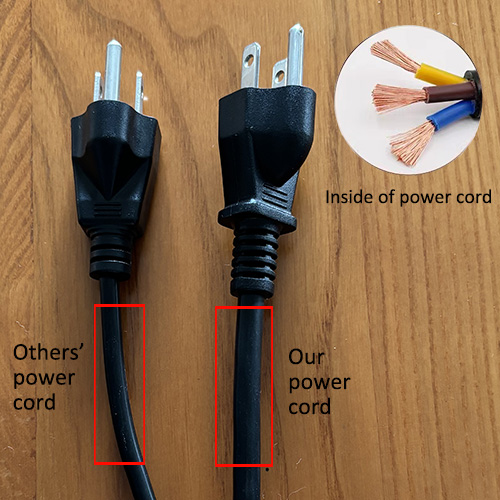

You can clearly see the difference in quality from the image below. Our power cords are thicker, better insulated, and securely attached to the grill units to prevent wear and potential hazards.

By choosing our grills, you're not only getting powerful performance and sleek design—you’re also gettingpeace of mind, knowing your equipment meets the highest electrical safety standards.

We are an experienced one-stop supplier for hot pot and Korean BBQ equipment.

If you’d like to learn more about our products, feel free to explore our website.

When opening or upgrading a Korean BBQ restaurant, the Korean grill table is one of the most important pieces of equipment. At our company, we supplyhigh-quality Korean BBQ tables that combine great design, durability, and customer-friendly features — trusted by restaurant owners worldwide.

1. A Wide Range of Styles

We offer multiple styles to match your restaurant’s concept:

-

Round grill tables– Great for groups and family-style dining.

-

Square or rectangular tables– Ideal for maximizing space and a modern look.

-

Built-in grill tables– Clean and professional appearance with seamless integration.

-

Movable grill units– Flexible for different setups or seasonal use.

No matter your floor plan or theme, we have a style that fits.

2. Premium Materials: Stainless Steel, Solid Wood & Stone

Our Korean BBQ grill tables are made usingtop-grade materials:

-

Stainless steelfor durability, easy cleaning, and a professional feel

-

Solid woodfor a warm, classic look and strong structure

-

Stone countertops(like granite or quartz) for heat resistance and an upscale finish

These materials are carefully selected to handle the high heat and daily use in busy restaurants.

3. Choose the Grill Type That Works for You

We support all popular BBQ cooking methods:

-

Charcoal grills– Authentic flavor, traditional style

-

Gas grills– Clean, convenient, and easy to control

-

Electric grills– Safe and suitable for indoor use, especially in smoke-controlled environments

Grill units can be built into the table or designed for easy replacement and maintenance.

4.Strong Frame Design with Functional Options

We focus not only on the surface but also on the structure beneath. Our BBQ tables feature:

-

Well-designed frame structurethat ensures long-term stability and strength

-

Options fortable legsortable barrels (drum-style base)

-

Table barrelscan be equipped with built-insmokeless systems, helping to remove oil smoke directly under the table while maintaining a clean, beautiful restaurant environment

Whether you want a modern open-leg design or a closed base that hides the smoke system, we’ve got the right solution.

5. Safety, Comfort, and Clean Air

Our tables are designed with user safety and restaurant air quality in mind:

-

Heat-insulated edgesfor safe, comfortable dining

-

Easy-to-clean surfaces

-

Optional smoke purifiersinstalled under the table barrel — hidden, efficient, and silent

This gives your restaurant a more elegant look without sacrificing function.

6. Trusted Service and Global Shipping

We offer more than just great products:

-

Strict quality control before delivery

-

Fast and secure global shipping

-

Professional support and after-sales service

Many restaurant owners reorder from us thanks to consistent quality and reliable service.

Our Korean BBQ grill tables combine smart structure, strong materials, and flexible design — from open-leg tables to closed barrels with built-in smokeless systems. Whether you're building a new restaurant or upgrading your current space, our tables are a smart, stylish, and durable choice.

Get in touch today for more details or a customized quote.

When purchasing Korean BBQ equipment for a restaurant or retail business, it’s not just about the design or price. Certifications play a crucial role in making sure your equipment is safe, legal, and suitable for your local market.

Whether you’re importing a Korean BBQ grill for your dining tables or installing smokeless BBQ equipment to create a cleaner indoor environment, the right certifications are essential. Here’s what you need to know.

The UL (Underwriters Laboratories) mark is required for electrical and gas-powered cooking equipment in the U.S. Many smokeless BBQ equipment systems and built-in Korean BBQ grills must meet these standards.

Why it matters:

Ensures compliance with local safety codes.

Required by many fire departments and health inspectors.

Common in commercial restaurant kitchens.

2. ETL Certification (North America)

ETL is similar to UL and widely accepted across the U.S. and Canada. It’s often used for electric BBQ grills, exhaust systems, and smokeless BBQ tables.Why it matters:

Accepted alternative to UL.

Covers both gas and electric Korean BBQ grill units.

Helps with insurance and inspection approvals.

3. CE Certification (European Union)

All electrical or gas-operated BBQ grills, including smokeless Korean BBQ grill systems, must carry the CE mark to be legally sold in Europe.Why it matters:

Proves compliance with EU health, safety, and environmental standards.

Important for equipment operating under high heat or power.

Required for importing and customs clearance in EU countries.

4. NSF Certification (Global – Food Safety)

If your BBQ grill comes into direct contact with food, like most Korean BBQ grill tops do, NSF certification ensures it's safe and hygienic.Why it matters:

Commonly required in restaurants in the U.S. and Canada.

Often expected for smokeless BBQ equipment with built-in heating surfaces.

Ensures easy cleaning and prevents contamination.

5. CSA Certification (Canada)

If you’re opening a Korean BBQ restaurant in Canada, look for CSA-cert

We provide high-quality Korean BBQ grills and smokeless BBQ equipment, fully certified for the U.S., EU, Middle East, and other markets. Whether you're opening a new restaurant or upgrading your kitchen, our products help you stay compliant, safe, and stylish.

Mechanism of action and preservative principle

preservatives are a class of additives that can inhibit microbial activity and prevent spoilage of products such as food or cosmetics. They play a crucial role in ensuring food safety and extending the shelf life of products. The following are the main mechanisms of action and principles of preservatives:

1. Interference with the enzyme system of microorganisms

Preservatives can inhibit enzyme activity by interfering with the enzyme system of microorganisms and disrupting their normal metabolic processes. This way of action makes microorganisms unable to grow and reproduce normally. 2.

2. Coagulation and denaturation of microbial proteins

Certain preservatives can coagulate or denature microbial proteins, thereby interfering with their survival and reproduction. This mechanism affects microbial life by altering the structure of proteins, causing them to lose their original function.

3. Altering the permeability of the plasma membrane

Preservatives can also alter the permeability of the plasma membrane of microorganisms, inhibiting the elimination of enzymes and metabolites from their bodies and leading to cell inactivation. By affecting the integrity of the cell membrane, this mode of action prevents the entry of nutrients and the elimination of wastes, ultimately leading to the death of the microorganism.

4. Affecting genetic material or the structure of genetic particles

Some preservatives are able to act on the genetic material or the structure of genetic particles of microorganisms, affecting processes such as replication of the genetic material, transcription and translation of proteins. This mechanism prevents microorganisms from reproducing and growing by interfering with their gene expression.

5. Influence of environmental factors

The action of preservatives is also influenced by environmental factors, such as temperature, pH, osmotic pressure, radiation, hydrostatic pressure, water source, nutrients, oxygen, organic growth factors, etc. These factors can affect the effect of preservatives, for example, under acidic conditions, certain preservatives have a strong inhibitory ability against molds, yeasts and bacteria.

To summarize

Preservatives inhibit the growth and multiplication of microorganisms through a variety of mechanisms, thereby extending the shelf life of products such as food or cosmetics. Understanding these mechanisms of action and principles of preservation helps to select appropriate preservatives to ensure product safety and effectiveness. In practical application, appropriate preservatives should be selected according to the specific use environment and target microorganisms, and used in strict accordance with relevant standards to avoid adverse effects on human health.

Moringa powder is a powder made from the grinding of moringa seeds, with a variety of effects and functions, as follows:

Nutritional supplements

Supplementary proteins: Moringa powder is rich in protein components, which can supplement nutrients for the human body, but also promote the synthesis of immunoglobulin, alleviate the symptoms of limb weakness due to the lack of protein in the body, which is conducive to physical health.

Supplemental trace elements: Moringa powder contains a variety of trace elements, such as amino acids, calcium, vitamin E, potassium, etc., appropriate consumption can supplement the body's need for trace elements, to a certain extent, to prevent malnutrition.

Enhance the body

Moringa powder contains chorism and alkaloids, has a certain antiseptic effect, appropriate consumption can be to a certain extent to improve the body's physical condition, but chorism can not be a substitute for medicines! Treatment of diseases.

Improve digestion

Chipotle powder contains a large amount of dietary fiber, can promote gastrointestinal peristalsis, conducive to the digestion and absorption of food, with the aid of improving the role of constipation.

Assist in lowering blood sugar

Some of the bioactive ingredients contained in chili powder can affect the secretion and utilization of insulin through a variety of pathways, thus assisting in lowering blood sugar.

Other effects

Chipotle powder can provide the human body with a large amount of vitamin C, vitamin A, Vitamin E, has a strong antioxidant effect, helps the liver to remove free radicals, slow down the aging of liver cells, enhance the detoxification function of liver cells, but also has the role of detoxification of alcohol to protect the liver.

Although moringa powder has many of the above effects, but can not replace the medicine to treat the disease. If uncomfortable symptoms occur, you should seek medical advice and treatment under the guidance of a doctor. In addition, excessive consumption of moringa powder may irritate the gastrointestinal tract, causing bloating, abdominal pain and other discomforts, and consumption by pregnant women may also lead to uterine contractions, triggering miscarriages, and is therefore contraindicated in pregnant women.

Comparison of Sweetness Values

Different sources state differently how sweeteners of mannitol compares to sucrose, but in general mannitol is less sweet than sucrose, though closer. Relevant information is as follows:

The sweetness of industrial grade mannitol is about 57% - 72% of sucrose3.

There is also information that the sweetness of mannitol is 50 - 70% of the sweetness of sucrose4.

There is also information that shows mannitol has a sweet taste, and that its sweetness is equivalent to 70% of that of sucrose6.

sweetness Significance of the comparison

In food applications, this sweetness comparison is of great significance. Because mannitol has the least water absorption among sugars and sugar alcohols and has a pleasant sweetness, it is often used as an anti-sticking agent in foods such as maltose, chewing gum, rice cakes, and as an anti-sticking powder in general confectionery, and as a low-calorie, low-sugar sweetener in foods for diabetic patients, bodybuilding foods, etc.36 It can provide a sweetness close to that of sucrose while meeting the needs of special populations for a low-calorie intake and playing a special physical role in the preparation of some food products. It plays a special physical role in the preparation of some foods.

Comparison of the sweetness of different sugar alcohols with sucrose

In addition to mannitol, other common sugar alcohols also differ in sweetness from sucrose. For example, the sweetness of erythritol is about 70% that of sucrose, maltitol is 90% that of sucrose, sorbitol is 60% that of sucrose, xylitol is as sweet as regular sucrose, isomaltrexol is 45-65% that of sucrose, and lactitol is 30-40% that of sucrose.4 These comparisons provide a clearer view of the position of the sweetness of mannitol in the context of many sugar alcohols.

Hazards of Maltitol

Maltitol is a common artificial sweeteners commonly used in the preparation of candies, chewing gum, chocolates and other foods. When consumed in moderation, maltitol is generally harmless and has benefits such as being low in calories, preventing dental caries and laxative. However, excessive consumption or long-term intake of large quantities may bring about a series of health problems.

1. Digestive problems

Bloating and diarrhea: Maltitol is not easily and completely absorbed in the intestines, and excessive consumption may lead to gastrointestinal discomforts such as bloating, diarrhea, and bowel sounds. This is because the unabsorbed portion will be metabolized by bacteria in the large intestine, producing gas and water, thus causing gastrointestinal discomfort.

Gastrointestinal mucosal damage: Maltitol is cold in nature and is not easily dissolved by digestive enzymes, it will accumulate in the gastrointestinal tract after intake, and repeated stimulation of the gastrointestinal tract may damage the gastrointestinal mucosa, resulting in gastric and abdominal pain.

2. Blood sugar effects

Despite the low glycemic index of maltitol, its excessive intake may still have some impact on blood glucose control, especially in diabetic patients. Prolonged intake of maltitol in large quantities may be absorbed by the body and converted to glucose, resulting in elevated blood glucose, which is detrimental to disease control.

3. Metabolic burden

Excessive consumption of maltitol will increase the metabolic burden of the liver and kidney. As maltitol is not easy to be digested and absorbed, it may be converted into fat and accumulate in the body if consumed in large quantities over a long period of time, thus leading to obesity and weight gain.

4. Allergic reactions

A few people may be allergic to maltitol and develop symptoms such as rash, itching and difficulty in breathing.

5. Nutrient absorption disruption

Maltitol may interfere with the absorption of certain minerals and vitamins, affecting the body's intake of other important nutrients.

6. Oral health problems

Although maltitol does not generally cause tooth decay, if consumed in excess, it may react with bacteria in the mouth that produce acids that can damage teeth and increase the risk of gum disease and tooth decay.

7. Cardiovascular Health Risks

Excessive intake of maltitol is not conducive to the dissolution of carbohydrates and fats. It also affects metabolism and tends to deposit fats in capillaries, leading to elevated blood pressure, and may even increase the risk of blood vessel blockage.

Conclusion

Maltitol, as a low-calorie sweetener, is safe when used in moderation, but for special populations (e.g., diabetic patients, hypertensive patients, and those with weak gastrointestinal function), it is recommended that it be used with caution and ingested under medical supervision. To minimize potential health risks, excessive consumption of maltitol should be avoided while maintaining a balanced diet and healthy lifestyle.

- Buddha Jump Over the Wall1

- Canned Abalone2

- Canned Turtle Soup1

- Edible Bird's Nest2

- Frozen Foods1

- Frozen Seafood8

- Jelly/Pudding Applications1

- Meat Product Applications2

- Others Applications5

- Plant-based meat Product Applications1

- SURIMI2

- Soft Candy1

- Soft Candy Applications4

- bottle1

- can end2

- packaging film2

- tableware3