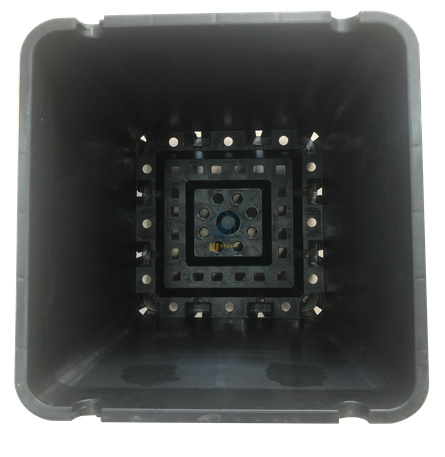

The 25L/30L Square planter Blueberry pot is our newly designed product, this growing barrel is expanded and improved on the basis of our 10L Dutch barrel.

The 25L/30L blueberry bucket is designed with high feet, so there is enough space between the ground and the bottom of the bucket to increase the air circulation at the bottom, which can reduce the risk of disease, and also increase the health of the plants and good drainage.

People desperately need better drainage, better airflow, better isolation of disease. This design not only optimizes drainage, but also allows air to enter the pot for better root health.

Reusable, durable pots are designed to maximize root development. This pot is great for fruits and vegetables, alternative crops, and woody ornamentals.

In agriculture, 8mm hollow transparent color is generally used as a covering material. It has good thermal insulation coefficient, light weight and high structural strength. It is favored by multi-span greenhouses in cold areas. But what I am sharing with you today is a case of using milky white sunlight panels in a corrugated greenhouse.

First, the use of PC greenhouses

Greenhouses are used as vegetable storage and sorting centers, cold storages, offices and other functions. However, since it is not suitable to build concrete buildings in the agricultural park, the design of the corrugated Polycarbonate Greenhouse with the top and the surrounding milky white material covering is used.

2. Polycarbonate Greenhouse model

1. The specifications and models of the steel skeleton of the solar panel greenhouse are 150*150*3.75*4500mm for the columns, 50*70*2.5mm for the truss beams, 50*100*2.5mm for the longitudinal truss beams, 375*2.2*4000mm for the water tank, and 375*2.2*4000mm for the greenhouse. The surrounding beam is 50*50*2.0,. The span of the greenhouse is 10.8 meters, and the bay is 8 meters. The greenhouse is 5 spans, 54 meters from east to west, 5 bays and 40 meters from north to south, and the building area of the greenhouse is 2160 square meters.

2. Greenhouse covering materials

The top and all sides of the greenhouse are covered with 10mm milky white sunlight panels, and the light transmittance of the sunlight panels is 10%. This can not only ensure the thermal insulation of the greenhouse and the use of normal greenhouse installation profiles, but also ensure that the interior of the greenhouse will not be too high to affect the temperature in the shed.

3. Advantages of milky white sunlight panel sorting center

1. It meets the functions of the park, builds speed blocks, is convenient for construction, and has low requirements for the bearing capacity of the foundation. Normally, it can be installed in 45-50 days.

2. Hot-dip galvanized light steel structure, the cost is more economical and practical, and the service life is more than fifteen years.

3. Non-large span design, strong wind and snow resistance. At the same time, the interior is bright and meets normal working conditions.

How much do you know about the intelligent greenhouse control system? Everyone who builds a greenhouse knows that when planting in a greenhouse, attention should be paid not only to irrigation and fertilization, but also to the temperature, humidity, and light in the shed, as well as to understand the indoor environment and to ventilate regularly. Therefore, a lot of manpower is required for actual planting in the greenhouse.

The intelligent control system is a product specially designed for greenhouses. The greenhouse can realize functions such as automatic irrigation and fertilization, automatic constant temperature and humidity, and automatic ventilation. Through automatic control, manpower can be saved. So how does the intelligent greenhouse control system realize automatic control? What is the specific principle? Let me introduce to you.

Regarding the principle of the greenhouse control system, we can give a few examples, such as the automatic control of the greenhouse. The system can monitor the temperature information of the greenhouse in real time through the room temperature sensor. When the temperature of the greenhouse is lower than the standard value, the system will automatically start the constant temperature system to adjust the temperature information of the greenhouse. When the room temperature reaches the standard value, the system will automatically close the constant temperature system.

In addition to controlling the smart greenhouse, there are also irrigation, fertilization, and ventilation. They are all the same principle. Soil moisture sensors monitor soil moisture information to realize automatic irrigation; use soil sensors to monitor soil nutrient information to realize automatic fertilization; use greenhouse carbon dioxide sensors to monitor greenhouse air quality and control automatic ventilation.

The above mainly introduces the control principle of the intelligent greenhouse, which is mainly used in the fields of automatic control of the agricultural greenhouse environment, high-tech agricultural demonstration projects, and agricultural scientific research and teaching.

The ebb and flow method, also known as flood and drain, is a hydroponic growing technique used to cultivate plants without soil. In this method, plants are placed in containers or trays filled with a growing medium, such as expanded clay pellets or rockwool. The containers are periodically flooded with a nutrient-rich solution and then drained.

Here's a step-by-step breakdown of the ebb and flow method:

1. Setup: The growing containers or trays are positioned on a table or bench. The containers usually have holes at the bottom to allow drainage.

2. Fill and flood: The containers are filled with the growing medium, such as expanded clay pellets or rockwool, which support the plant roots. Then, the table or bench is flooded with the nutrient solution, which is pumped from a reservoir or storage tank. The nutrient solution should cover the entire growing medium, saturating it.

3. Nutrient absorption: As the table or bench floods, the plant roots absorb the nutrient solution along with oxygen. The nutrients in the solution provide the essential elements needed for plant growth.

4. Drainage: After a specific duration, usually a few minutes, the flood is stopped, and the nutrient solution drains back into the reservoir or storage tank. Gravity or a pump system can be used to facilitate the drainage.

5. Resting period: Once the flood is drained, the plants have a period of rest where they are exposed to air. This allows the roots to receive oxygen, promoting healthy growth.

6. Cycling: The flood and drain cycle repeats at regular intervals, such as every few hours or several times a day, depending on the plant's requirements and the system's setup. The timing and duration of the flood and drain cycles can be adjusted for optimal plant growth.

The ebb and flow method provides plants with a periodic supply of nutrients and oxygen, creating an environment conducive to rapid growth. It is a flexible and versatile hydroponic technique suitable for a wide range of plant species and can be used in both small-scale and large-scale growing operations

The ebb-and-flow, also known as flood and drain, is a hydroponic system technique used for growing plants. The purpose of the ebb-and-flow system is to provide periodic flooding and draining of the plant roots with nutrient-rich water. The cycle typically involves flooding the growing tray or container with the nutrient solution, allowing the roots to uptake water and nutrients, and then draining it away.

The ebb-and-flow system serves several purposes:

1. Nutrient uptake: By periodically flooding the growing medium or container with a nutrient solution, plants can absorb the necessary water and nutrients they need for growth. This helps ensure that the plants receive an adequate supply of nutrients for healthy development.

2. Oxygenation: During the flooding phase, the roots are submerged in water. When the water drains away, it allows for the replenishment of oxygen around the roots. Oxygen is vital for root respiration and the prevention of anaerobic conditions that can harm the plant roots.

3. Prevention of waterlogging: The ebb-and-flow cycle helps prevent waterlogging of the roots by allowing excess water to drain away. This promotes healthy root growth by providing a balance between nutrient uptake and oxygen availability while minimizing the risk of suffocating the roots.

4. Irrigation and hydration: The ebb-and-flow system provides an effective means of irrigating the plants. The flooding phase ensures that the growing medium is thoroughly hydrated, enhancing plant growth and overall moisture management.

5. Nutrient circulation: The periodic cycling of the nutrient solution helps maintain proper nutrient circulation and prevents the buildup of salts and nutrient imbalances that can occur in stagnant systems.

Overall, the ebb-and-flow system provides an efficient way to deliver water, oxygen, and nutrients to plants in a controlled and optimized manner, promoting healthy growth and optimal plant.

To say that the field of greenhouse cost is the cheapest form of Plastic Single Span greenhouse, then it is inserted in the vault. It is a form of direct insertion into the ground with the curved sides of a circular tube. This kind of greenhouse is used a lot in central China and South China, and is favored by ordinary growers because of its low cost.

First, Tunnel greenhouse data parameters

Greenhouses generally span 6 meters to 9 meters, 1 meter to 2 meters high at the shoulder, 3.5 meters to 4.5 meters high at the top, and can be arbitrarily long according to the terrain.

This kind of greenhouse design data is relatively few, because its structure is simple, the foundation is usually inserted into the ground or simple concrete foundation, the skeleton is usually galvanized round pipe, the wind and snow resistance is relatively poor.

There are two vents on both sides of the greenhouse, which are attached with insect nets to prevent the pollution of insects with viruses and cause losses. Simple doors are set on both sides to provide simple protection and heat preservation.

Two, insert the use of greenhouses

The northern region can be used as a cold shed, the southern region can be used as a shelter for planting, can grow vegetables, ordinary flowers (non-high-grade potted flowers), edible fungus cultivation, etc.

Third, the cost of greenhouses and influencing factors

The main material inserted into the greenhouse is arch rod, longitudinal rod, shed film and other small accessories materials. The arch is available with diameters of 25, 32, and 48 tubes and thicknesses ranging from 1.5 to 2.0. The main types of longitudinal rod are 25 tubes in diameter and vary in thickness from 1.5 to 2.0. There are many kinds and brands of greenhouse film, such as po film, pe film, etc., the thickness is from 4 wire to 15 wire, the service life of the greenhouse film is from one year to eight years. Therefore, there are many differences in the cost of greenhouses, ranging from 5 to 7 dollars per square meter.

This type of greenhouse still has a large market share because of its low cost and simple installation, but it is worth noting that it is best not to buy cold galvanized skeleton material, which will rust in one or two years. It is necessary to choose hot galvanized skeleton material to drink products.

As for the comparison between NFT (Nutrient Film Technique) and DWC (Deep Water Culture), they are both popular hydroponic systems used for cultivating plants. Both methods provide a constant supply of water and nutrients to the plants without the need for soil. However, they have some differences:

1. NFT: NFT is a hydroponic system where a thin film or stream of nutrient-rich water is continuously circulated over the bare roots of the plants. The roots are exposed to the air and are suspended in channels or gullies. NFT systems require a slope to allow the nutrient solution to flow and are suitable for growing leafy greens and herbs. They require careful management of nutrient levels and flow rates to prevent drying out or waterlogging of the roots.

2. DWC: DWC is a hydroponic system in which plant roots are submerged in a nutrient-rich solution. Plants are typically grown in net pots that are suspended in a reservoir filled with the nutrient solution. Air stones or diffusers are used to provide oxygen to the roots. DWC systems are relatively easy to set up and are suitable for a wide range of plants. They can support larger plants and generally require less maintenance compared to NFT systems.

Choosing between NFT and DWC ultimately depends on factors such as the types of plants you want to grow, the available space, your level of experience, and personal preferences. Both methods have their advantages and disadvantages, so it's important to consider your specific needs and resources to make an informed.

1. Ageing

Usually we do a hand tear test to determine whether the film has aged. In addition, we can test different places to see whether it is local aging or overall aging. The most common problem is that farmers use sulfur or halogen ( Cl, Br , etc.), which makes the UV stabilizer added to the film lose its effectiveness, thereby accelerating the aging of the film. When the film contacts iron, wood, PVC , etc., it will also cause the film to age faster.

(Note: To prevent premature aging of the film, please minimize the use of chemicals containing sulfur , chlorine, etc.)

2. Poor dripping

Usually we judge the dripping problem from the following aspects:

1 ) Check whether the installation is correct by checking the printed “This side faces the ground” on the film;

2 ) Production and installation time. On the one hand, it often takes a certain amount of time for the drip agent to take effect, especially in the very cold north. On the other hand, because the drip agent is constantly migrating from the inside to the outside, the drip agent on the surface is constantly washed away by water. After a period of time, the concentration of the drip agent is low to a certain level and eventually loses its effect.

3 ) Is the film installation angle appropriate? If the angle is too flat, the mist droplets on the film surface cannot flow down from both sides well, but will directly drip onto the plants.

4 ) Whether the film is installed well, for example, there should be no creases, because the droplets will stay in the creases, which is equivalent to continuously dissolving the drip agent there, and finally causing the area to fail prematurely.

5 ) The temperature difference between the inside and outside of the greenhouse and the humidity inside the greenhouse. When the humidity inside the greenhouse is not enough, the droplets cannot form a water film on the surface of the membrane, causing the droplet agent to precipitate and become powder attached to the surface of the membrane.

3. Films stick together

When the film is at high temperatures, the polymer chains untangle and fuse together, causing the film to stick together.

Different materials have different softening points. For example, the softening point of LDPE is about 95°C, the Vicat softening point of LLDPE is about 100°C , and the softening point of EVA is about 60-75°C . The higher the VA content, the lower the softening point.

In order to avoid this problem, the most important thing is to avoid exposing the rolled sheets to the sun and avoid high temperatures and high pressures.

Intelligent fixed roof vents continuous PE film greenhouses are specially designed for the African market to produce year-round, with the advantage that the climate inside the greenhouse can be regulated by the cooling system.

How can the cooling system of our greenhouse be lowered to the temperature of normal plant growth?

Today Jamie from Xiamen Wellgain Greenhouse Engineering Co., Ltd. would like to shares with you an article about an economical effective cooling solutions of African intelligent fixed roof vents greenhouse for your reference.

An external shade net is a layer of netting installed 50cm or more above the top of the glasshouse parallel to the roof. It is the most direct way of cooling by blocking the sunlight directly outside.

The design focus of the shade net must be higher than 50cm above the roof in order to achieve the best effect and facilitate the flow of airflow in the lower part of the greenhouse.

This reduces the amount of solar radiation and thus heat entering the greenhouse.

The effectiveness depends on the type of shading material used and the percentage of light it blocks, to the best of our knowledge, external shading can reduce internal temperatures by about 5 ℃ ~ 7 ℃(FYI) depending on the intensity of the shading.

Greenhouse in the tropical regions, the indoor temperature is generally higher than the outdoor air temperature 4 ℃ ~ 6 ℃(just for reference).

Through the use of external shading screen system, the temperature inside the greenhouse can be lower than the outdoor temperature at the same time 1 ℃ (just for reference).

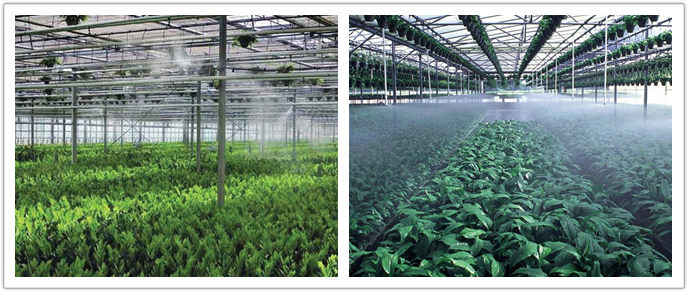

2: High pressure fogging system

High-pressure fogging machine cooling principle is to use the principle of evaporation and heat absorption is through high-pressure water beads into 0.165mm diameter spray, through evaporation to take away heat.

This system uses high-pressure pumps to create a fine mist or fog of water droplets that evaporate quickly. The evaporation process absorbs heat from the air, thus cooling the environment. The reduction in temperature due to a fogging system can vary greatly depending on the external temperature and humidity levels, but reductions of 3 ℃ ~ 6 ℃(just for reference) are common, with greater reductions possible under ideal conditions.

Combining an external shading system with a high-pressure fogging system in a greenhouse can be highly effective in controlling temperatures, especially in a tropical climate like that in Africa regions which the humidity is not high.

The humidity in the greenhouse may reach 95% or more after running of high pressure spraying, but after 1 hour to 2 hours, the humidity in the greenhouse will be reduced back to the original humidity(just for reference).

- Buddha Jump Over the Wall1

- Canned Abalone2

- Canned Turtle Soup1

- Edible Bird's Nest2

- Frozen Foods1

- Frozen Seafood8

- Jelly/Pudding Applications1

- Meat Product Applications2

- Others Applications5

- Plant-based meat Product Applications1

- SURIMI2

- Soft Candy1

- Soft Candy Applications4

- bottle1

- can end2

- packaging film2

- tableware3